Introduction to Pipe Relining

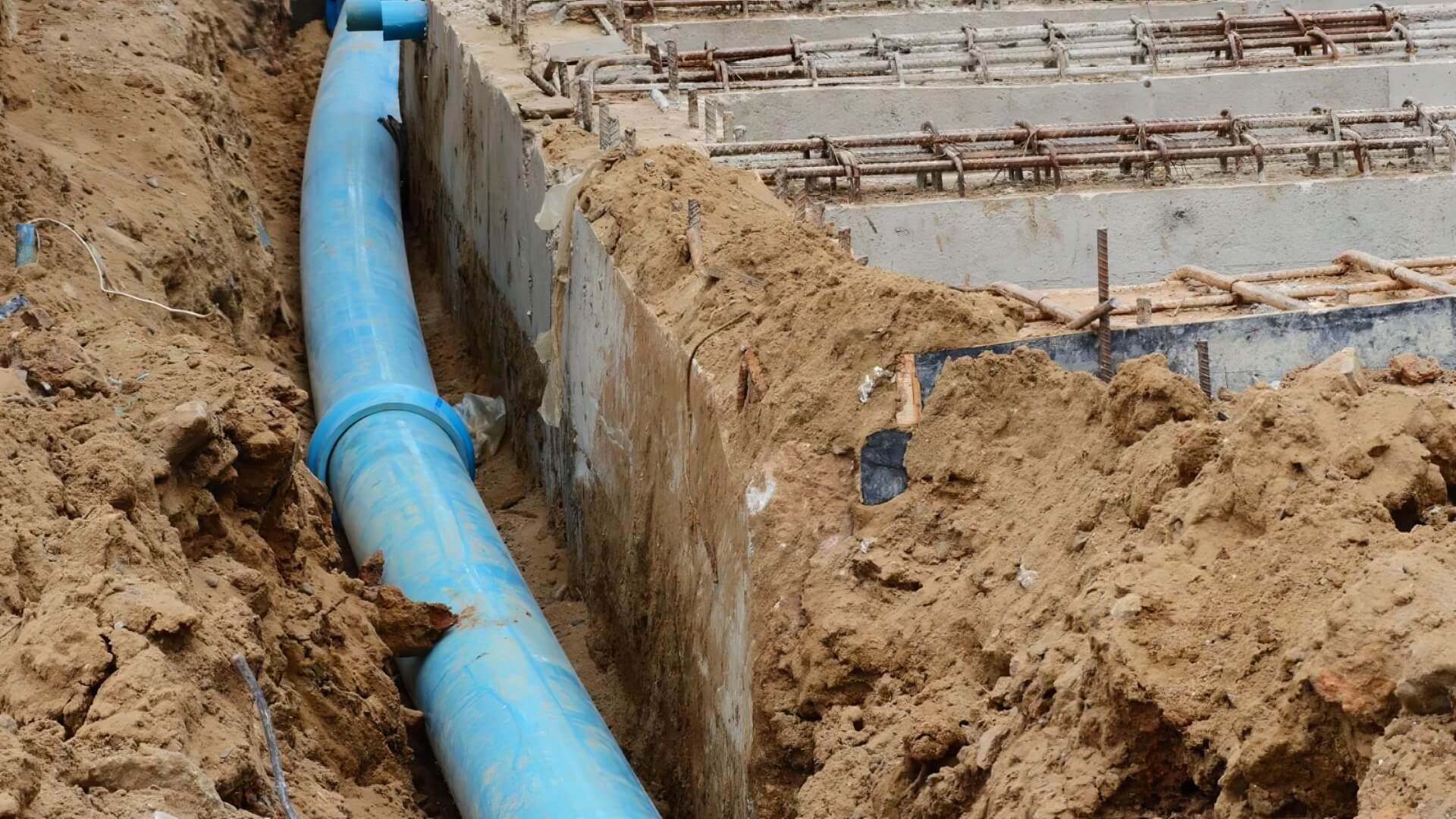

Pipe relining revitalises compromised pipes through an internal epoxy coating application, negating the need for lengthy excavations or full pipe replacements. The resultant cured epoxy layer provides a durable patch for leaks, enhances flow, and combats corrosion.

How Pipe Relining Works

The pipe relining process, a trenchless method pipe repair technique, revives damaged pipes from within. Here’s a step-by-step overview of the pipe repair method we use:

- Initially, a plumber utilises CCTV cameras to assess the pipe damage, verifying its suitability for relining by determining the size and length of the pipe.

- The pipe is then cleaned up to remove any built-up debris or deposits using high-pressure water jets.

- Once cleaned, you’ll wonder how long the flexible epoxy lining, coated with a bonding agent, is readied to be inserted into pipe through an access point. This is usually an existing cleanout or tap.

- The liner is expanded using compressed air so it presses firmly against the inner walls of the pipe, ensuring it was able to seal properly.

- As the resin cures, or hardens, it transforms into a robust curedinplace pipe within the compromised section. Curing with UV light takes around 2-3 hours.

- Lastly, small holes are drilled through the ends of the liner to reestablish any connections or lateral joins.

Plumbing services use trenchless repair methods to renew pipes without excavation, even if they are deep underground or hidden.

The job was efficiently completed by our team in a swift 1-2 days with minimal disruption to your property. Upon completion, your pipes have a smooth surface that wards off future build-up and deterioration, giving you peace of mind that you won’t hesitate to use them again for any plumbing requirements. The epoxy barrier also protects against water leaks, restoring flow capacity and water pressure.

Materials Used in Pipe Relining

Pipe relining effectively rehabilitates damaged sewer pipes, with the utilised epoxy resins presenting no risk in terms of durability and suitability for potable water lines. Determining what pipe material to use is critical, and these high-strength epoxies, celebrated for their quality work, make sure they are ideally suited for potable water pipe applications. Once hardened, they form a smooth, impermeable barrier that seals cracks and holes in the original drinking water pipes.

Epoxy resins have several advantages that make them well-suited for pipe relining:

- They are extremely strong and long-lasting, with a lifespan matching or exceeding that of traditional piping.

- Epoxies are chemically inert once cured, ensuring they won’t cause corrosive damage to existing copper pipe, leach chemicals, or impact the standard of your drinking water.

- These resins can repair a wide range of standard plumbing pipe materials, like cast iron, PVC, concrete, clay, and copper.

- Epoxy liners are flexible before curing, allowing insertion via trenchless methods with minimal excavation.

- They prevent build-up and restrict microbial growth thanks to an ultra-smooth finish.

- The plumber took time to talk me through the procedures and cleaned up after work, ensuring I understood how the majority of epoxies used are suitable for drinking water and have NSF/ANSI 61 certification.

To comprehend the versatility of pipe relining, note that some systems may also incorporate materials such as acrylic-based resins or UV-cured glass liners, besides epoxy. But in the world of relining technology, epoxy remains the most popular and reliable option. The cured resin is inert, non-toxic and provides a protective barrier between damaged pipes and drinking water.

Safety of Relined Pipes

When done correctly using proper materials, relined pipes are entirely safe for transporting hot water. Any concerns about potential leaching from epoxy resins are misplaced since once fully cured, these liners are completely inert. This means they cannot contaminate water or affect its taste or quality in any way.

Specialised providers, such as Redline, skilfully resolve sewage complications through industry-standard composite resins like epoxy, in strict compliance with NSF/ANSI safety standards for potable water. They did great job and I would highly recommend their work for their outstanding results, as their Polyurethane (PU) and Ultraviolet (UV) cured glass liners also contain zero BPA, VOCs, or other harmful additives. Comprehensive third-party testing confirms these liners do not release any harmful chemicals into drinking water.

Relined pipes provide a smooth, seamless barrier between damaged pipes and your entire piping system. This prevents corrosion and build-up of sediments, microbes and minerals in your water line that could potentially compromise safety. Hydraulically smoothed epoxy liners leave no cracks or crevices in your sewer line where contaminants can accumulate.

In many cases, relining old pipes can improve drinking water safety compared to unlined pipes that may contain lead, asbestos or sedimental corrosion. There are even NSF-approved epoxy coatings specifically designed to encapsulate lead pipes and render them safe.

Preventing Bacteria Buildup

There are several important steps involved in preventing bacteria buildup in relined pipes:

- Thorough cleaning and sanitisation of the pipes prior to relining removes any existing bacteria, biofilm deposits, or sediment.

- The smooth, impervious epoxy barrier prevents future bacterial growth by eliminating cracks and corrosion where microbes could accumulate.

- Maintaining adequate disinfectant residuals, proper pH and flow levels inhibits microbial regrowth after relining.

- Each year, annual inspections leveraging camera technology can detect any buildup early, allowing for prompt cleaning before it becomes problematic.

- Flushing the pipes periodically clears out any new bacterial growth or sediments over time.

- Using EPA and industry approved potable epoxy liners ensures the new barrier doesn’t leach any substances that encourage bacteria.

- Sealing off dead ends and branches in the pipes removes areas where water can stagnate and bacteria multiply.

I was very happy with the happy service, discovering that after strict sanitisation and the use of non-leaching epoxy liners, relined pipes ensure optimal conditions to keep drinking water safe and bacteria-free.

Avoiding Lead Contamination

Pipe relining effectively mitigates lead contamination in drinking water, a crucial consideration for older properties with lead plumbing susceptible to corrosion. Relining coats these pipes with an impermeable epoxy barrier that encapsulates the lead and stops it leaching into the water.

Epoxy liners have been proven to reduce lead levels in drinking water to well below the EPA action level of 15 parts per billion. Tests show lead concentrations from properly relined lead pipes decrease by between 75-99%. The smooth epoxy surface also prevents buildup of sediment that could re-expose bare lead.

Epoxy’s resistance to corrosion provides long-term protection against lead leaching. Relined pipes, designed to make your pipe last and tucked securely under building foundations, won’t develop pinhole leaks or corrosion that could re-contaminate drinking water. Annual pipe inspections can also identify any damage early before lead leaching recurs.

Pipe relining provides a safe, effective solution for homeowners, ensuring they’re conscious that the service was committed to delivering a long-lasting, quality fix. The relined pipes encapsulate the lead and provide a durable barrier to prevent drinking water contamination for decades.

The smooth epoxy surface also prevents buildup of sediment that cou/ANSI 61 standards. The epoxy barrier must demonstrate zero leaching of any contaminants into test water at harmful levels. Once cured, samples are extracted from the liner to test for leaching potential per NSF/ANSI 61 standards. Following rigorous testing and certification protocols for materials and installation ensures relined pipes maintain high standards for clean, potable water.

Pipes are pressure tested and inspected before relining to ensure structural integrity and proper curing through monitored time and temperature.

Benefits of Pipe Relining

The benefits of pipe relining over traditional pipe replacement include:

- Minimal disruption - The trenchless technique of relining saves your property from excavations and damage to walls or floors.

- Speed - Generally accomplished within 1-2 days, relining is a swift alternative to the weeks-long process of pipe replacement.

- Cost savings - Pipe relining cuts expenses substantially, often by half or more relative to pipe replacement costs.

- Longevity - Epoxy liners can extend the lifespan of pipes by 50-100 years.

- Improved flow - The smooth sealed lining increases water pressure and flow rate.

- Reduced leaks - The epoxy barrier seals cracks and holes to prevent water leaks.

- Prevents root intrusion - The liner offers a safeguard designed to prevent tree root intrusion from growing into and cracking pipes.

- Versatility - The epoxy resin works on almost all plumbing materials from cast iron to PVC.

- Environmental benefits - Relining avoids waste and disruption associated with pipe replacement.

- Maintenance of property value - Home buyers often prefer relined pipes over partially replaced pipes.

Our relining services offer unmatched durability, flow performance, and cost-efficiency, making it a sensible choice for pipe restoration.

Pipe Integrity and Leak Prevention

Pipe relining helps maintain the structural integrity of existing pipes and prevent leaks like those caused by a broken pipe, in several ways:

- The epoxy coating can help seal cracks, holes, and joints that are prone to leaking.

- It was really reassuring to learn that relining prevents corrosion, erosion, and the incursion by tree roots, which commonly weaken pipes over time.

- The smooth interior curbs the risk of our blocked pathways that might lead to pipes bursting.

- It adds a protective barrier that stops root intrusion from trees or plants.

- Structural strength is restored in degraded pipes.

- Any displaced joints or misalignments are stabilised.

- The liner withstands pressure fluctuations and temperature changes.

- Annual inspections, often aided by advanced leak detection technology, can catch any new leaks breaks early for quick patching.

- Monitoring water pressure identifies potential trouble spots proactively.

By renewing old pipes from the inside, pipe relining keeps them in optimal working order. It provides the assurance that your plumbing system will keep supply clean water reliably while avoiding leaks that lead to water waste and property damage.

Cost Savings

Pipe relining does provide substantial cost savings compared to full pipe replacement. On average, relining costs 50-70% less than replacing pipes. Here are some comparisons for situations involving broken pipes:

- Typical costs for pipe relining range from $70-150 per linear foot, while pipe replacement averages $200-250 per foot.

- Relining a 75 foot drain pipe may cost $8,000-$12,000 versus $18,000-$22,500 to dig up and replace the pipe.

- For a full home repipe, new pipe lining averages $7,000-$15,000 compared to $15,000-$25,000 for a complete new plumbing system replacement.

- Commercial buildings save 50% or more on relining costs for risers, mains, drains and more compared to tearing up slabs and foundations.

The cost savings primarily come from avoiding the major demolition, excavation, disposal and restoration work involved with pipe replacement. For property owners, relining is ideal as it employs small access points instead of creating expansive excavated areas.

Even with more affordable upfront costs, relined pipes, when installed correctly, have a lifespan on par with new pipes and pricing that was very reasonable. The epoxy or resin materials are extremely durable and the pricing was very reasonable. Overall, pipe relining provides a highly cost-effective and long-lasting pipe repair solution for both residential and commercial properties.

Minimal Disruption

One of the biggest benefits of pipe relining is the minimal disruption it causes compared to full pipe replacement. Because it is a trenchless technology, pipe relining can be completed without need dig up your yard, resulting in far less impact on your home or business.

The pipe relining process is typically finalised within just 1-3 days. We provide no-dig solutions and we would confidently recommend setup of equipment and the new liner outside your building for storm water management, as our team clearly knew what they were doing. After cleaning the pipes, they inserted flexible epoxy resin into an existing pipe through drains or cleanouts.

New epoxy liners can be installed through minor access points, and our team ensures maximum satisfaction without need for undue disruption to walls, flooring, or landscaping.

Unlike pipe replacement, you won’t have to deal with jackhammers, backhoes, dump trucks or excavators digging massive trenches on your property. Repiped areas can be returned to use straight away instead of waiting days or weeks for extensive restorations, showing how quickly we came out to address your concerns. The minimal access points eliminate damage, so when we come out to complete the job, your yard, landscaping and interior spaces stay intact.

By keeping disturbance to a minimum, pipe relining allows plumbing repairs to be completed rapidly and cost-effectively with the least impact on your home or business. The short completion time and small footprint make it an ideal pipe renovation solution.

Long Lasting Solution

Compared to conventional methods, pipe relining provides notable longevity. High-quality epoxy resins can extend the lifespan of pipes by 50-100 years.

Properly installed epoxy liners are expected to last the full lifetime of the building or property before needing replacement. The material is so robust that relined pipes often outlast even new piping installed during remodels. There are cases of epoxy liners functioning smoothly for over 50 years and counting.

This exceptionally long service life affords great peace of mind to homeowners and businesses. It eliminates the need for recurring pipe repairs, replacements, and disruptions. The permanent epoxy barrier maintains the integrity of your plumbing system for generations.

With routine inspections and maintenance, relined pipes enter your home as a century-long solution for pipes that have deteriorated over the years. The strength and longevity of the epoxy liner also saves thousands in future plumbing costs compared to short-term fixes. In terms of reliability and lifespan, pipe relining is a forward-thinking investment in your propertys plumbing infrastructure.

Long Lasting Solution

Compared to conventional methods, pipe relining provides notable longevity.

Industry Acceptance of Pipe Relining

Pipe relining has gained widespread acceptance within the plumbing industry asn (AWWA) now endorse pipe relining as a long-term piping solution.

The Canadian Standards Association certifies pipe relining products that meet qualitytice to renovate aging water infrastructure. The technology is seen as a critical tool in reducing water main breaks and leaks, ensuring greater system reliability.

Endorsed by experts for its efficiency, pipe relining is now recognised as a key method for restoring degraded piping.

Conclusion

Pipe relining has emerged as a highly effective and safe solution for restoring deteriorated water supply pipes. The smooth epoxy barrier renews old water pipe from the inside out, preventing leaks, breaks, blocking contamination and improving water flow. With minimal excavation needed, pipe relining allows for major pipe repairs with much less disruption compared to traditional pipe replacement. And the extreme durability of relined pipes ensures they will provide reliable delivery of clean, safe drinking water for decades to come. Pipe relining has emerged as a highly effective and safe solution for restoring deteriorated water supply pipes.

Recognised for sustaining pipe integrity and providing top-tier plumbing services, St Marys Plumbing stands out with its expertise in pipe relining. Trust us as your local professionals for secure and premium-quality relining solutions.