What Causes Low Water Pressure

There are several common causes your plumbing service frequently addresses for low water pressure in homes and businesses:

- Pipe obstructions - Accumulated mineral deposits, corrosion, or invading tree roots clog the flow of water, highlighting how a damaged pipe can limit pressure.

- Water leaks - Cracks and holes from broken pipes can result in significant water leaks, allowing vital water to escape the system before reaching the faucet, lowering pressure.

- Old plumbing - Deteriorated and rusty water lines may falter when supplying sufficient water volume and pressure, causing low water pressure.

- Insufficient pipe size - Undersized pipes bottleneck water flow, unable to keep up with demand.

Pipe relining solutions—sometimes inclusive of a pressure regulator—remedy low water pressure by addressing obstructions, leaks, and corrosion in damaged pipes. This pipe relining method is able to reline the plumbing of your home business with an epoxy resin, capably restoring integrity, preventing leaks, and smoothing the inner surface. Resultantly, water flow capacity improves and water pressure in your property is restored, bypassing the substantial disruption associated with traditional pipe replacement.

How Pipe Relining Works

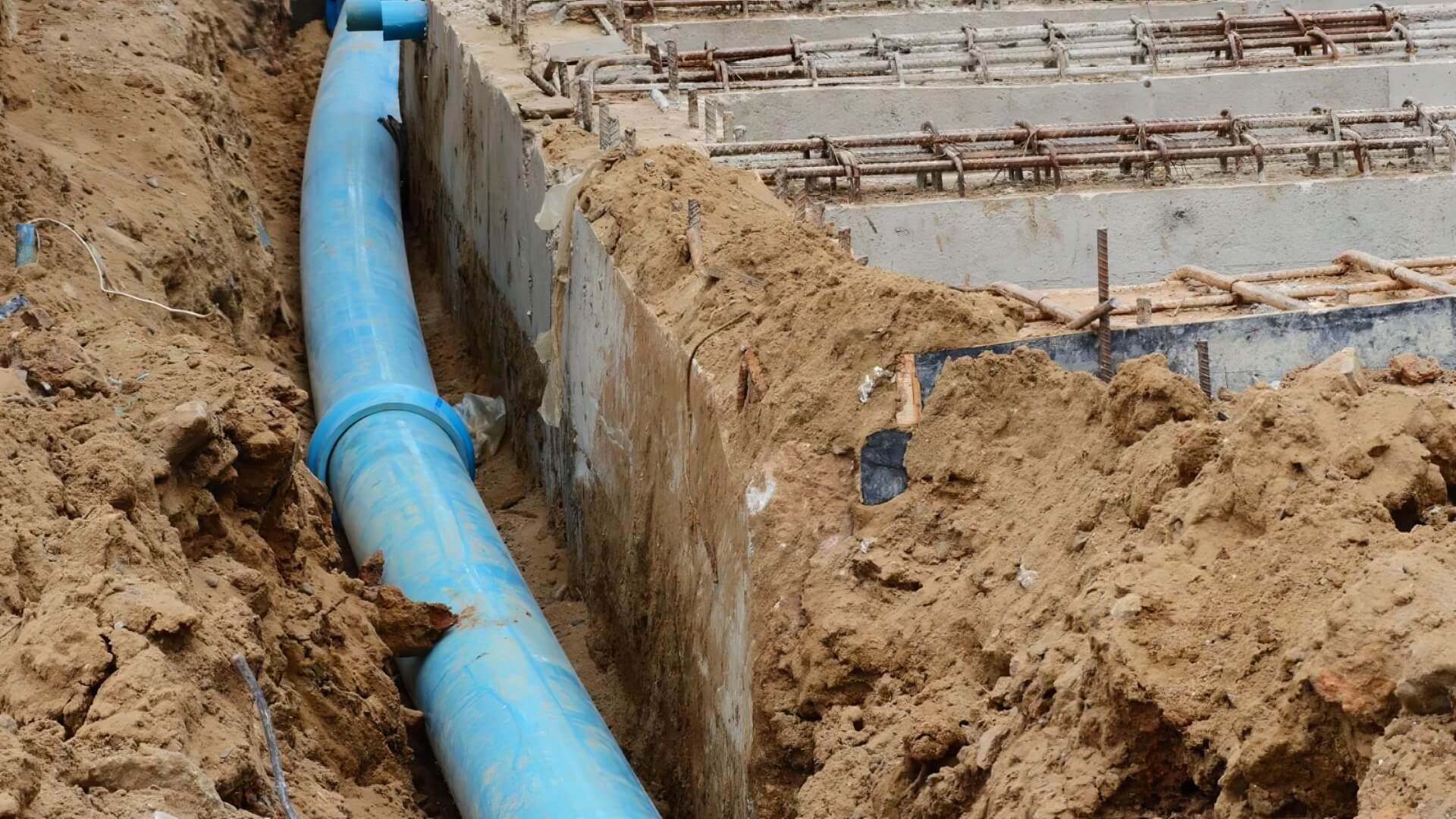

Trenchless pipe technology is a restoration technique that reinstates your system’s water pressure, functioning efficiently without excavation. The key steps involved are:

- A plumber will guide you through the CCTV camera inspection, meticulously examining the drainage system to pinpoint pipe issues.

- Access points are subsequently created within your plumbing system at strategic locations to get pipe interiors ready for rehabilitation.

- A supple epoxy resin tube, also recognised as a liner, threads through, conforming snugly to the pipe within.

- The liner is inflated, bonding tightly to the inner walls of the pipe within your hot water system.

- The epoxy resin is then cured, either with hot water or UV light, hardening into a smooth new inner pipe surface.

- Once cured in your home’s pipes, the liner restores flow capacity and seals cracks and leaks. The access points are also sealed up, finishing the repair.

Trenchless pipe relining techniques successfully boost water pressure by smoothing out the inner pipe surface, clearing obstructions, and sealing leaks. The seamless epoxy liner can withstand high water pressure, preventing corrosion and lasting for decades. Eliminating the need for pipe replacement, relining ensures a resilient restoration to peak functionality.

When Pipe Relining Can Help Low Water Pressure

Does pipe relining work? It has proven to be extremely effective over time in restoring water pressure issues caused by common plumbing problems like pipe obstructions, leaks, corrosion, and undersized pipes. Here are instances where sewer pipe relining can effectively mitigate low water pressure:

- Old galvanised or cast iron pipes, including the main Sydney water line near the water metre, experiencing corrosion from your water’s mineral buildup, can be sealed and receive a relined pipe with relining solutions for enhanced flow.

- Tree root infiltration blocking your sewer line or storm water conduits can be neatly managed with drain pipe relining, deftly thwarting future root encroachment on your premises.

- Pipe damage leading to water loss and reduced pressure - The epoxy liner serves as a permanent sealant, mending cracks and holes.

- Outdated piping with restrictive bends or joints - Pipe relining allows for optimal water flow by smoothing out twists and sharp angles.

The process can also prevent further issues with your water pipes down the track.

Pipe Relining Process Step-By-Step

- CCTV inspection - A professional guides a camera through the pipes to identify blockages, cracks, root incursions, and pinpoint where relining is needed.

- Access point creation - Precise openings are made in the pipe system to introduce the epoxy resin liner.

- Epoxy liner installation - The flexible epoxy resin tube is fed through the pipe and inflated to fit tightly.

- Liner curing - The resin liner is solidified with hot water or UV light to create a seamless interior pipe surface.

- Finalisation and testing - Sealing of access points, joint testing, and confirmation of watertight pipe renewal complete the process.

Pipe relining far surpasses traditional methods in that it’s less intrusive compared to conventional pipe replacement, thus shielding your property’s visual appeal. With just a few small access points cut rather than digging trenches, it allows pipes to be restored with minimal property damage or landscaping disruption.

Pipe Relining vs Replacement

Pipe relining and full pipe replacement offer two strategies for restoring a damaged pipe, each with its distinct advantages:

Costs

Relining is economically efficient by refurbishing and strengthening pipes without the necessity of a complete system overhaul. Given its affordability, with typical costs of $80 to $250 per metre compared to over $400 for full pipeline replacement, relining stands out as the financially savvy option.

Disruption

The minimally invasive relining process requires only small excavations for pipe access, thus reducing property disruption. So relining limits property damage and landscaping disruption.

Time

How long does pipe relining take? Typically, a project can be completed within 1-3 days, with no lengthy replacement process that can take weeks. The faster turnaround reduces downtime and associated business losses from lack of drainage/water access.

Lifespan

A structural pipe lining forms a corrosion-resistant barrier, enduring for over 50 years, matching the lifespan of new installations. Fully replaced pipes have a similar maximum lifespan. So both return long-term functionality.

In essence, let us manage your most common but fundamentally robust pipes using pipe relining, our endorsed approach for rapid and minimally invasive restoration. However, in cases of severe damage, full pipe replacement may be the only viable option.

- Chronic low water pressure, particularly during high usage, suggests internal pipe issues that impede water flow.

- Leaky pipes - Visible leaks or damp areas along a pipe indicate breaches that relining can repair, strengthening system pressure.

- Discoloured water - The presence of rusty, brown, or particulate-laden water signals eroding pipes unleashing mineral deposits.

- Blocked drains due to tree roots or mineral buildup are ideal for relining, averting repetitive problems.

- Odours - Indoor sewer gas odours emanating from the drainage system suggest openings that require sealing.

- Noisy pipes - Clanging, banging or hammering sounds when opening/closing taps signals internal corrosion wear and obstruction.

If you’re encountering these pipe issues and wondering if pipe relining is suitable, it’s most likely the best solution your home requires for low water pressure woes, ensuring long-term functionality.

Signs Your Pipes Need Relining

A number of telltale signs may suggest the need for pipe relining:

Discolouhedding mineral buildup.Pipe Relining Materials and Durability

Pipe relining employs a continuous epoxy resin layer to internally coat impaired pipes. This tough, flexible plastic polymer compound is the ideal lining material to fix your pipes, boasting high bond strength, corrosion resistance, and long service life.

Once set, the epoxy resin forms a smooth, impervious surface within pipes, preventing corrosion and enduring for over 50 years. So you can expect relined pipes that were expertly fitted and are very durable, easily outlasting traditionally replaced metal and concrete pipelines.

The adaptable resin in pipe relining bonds with common plumbing materials such as copper, cast iron, and PVC. Find out more about how your pipe relining allows custom moulding to the pipe shape during installation. So relining works within the existing pipe structure to return to optimal flow capacity and water pressure without needing full replacement.

With durability matching or exceeding new pipes, epoxy relining brings long-term functionality and stability to residential, commercial and municipal plumbing assets. This continuous, joint-free approach yields optimal water flow, precluding the need for additional repairs for many years.

Choosing a Professional Pipe Relining Service

Key factors to consider include:

- Staff credentials - The expertise of our team, comprising fully certified drainage technicians and plumbers licenced for pipe relining, ensures quality work backed by comprehensive qualifications and training.

- Range of services - Select a provider that offers comprehensive drain repair, including inspections, cleaning, root cutting, and leak detection, all performed in-house prior to relining.

- Equipment & materials - They should have the latest relining equipment and use high-density epoxy resins that meet industry standards for bonding, thickness and curing times.

- Warranties - Guarantees on workmanship and materials, often extending over 50 years for pipe liners, underscore service reliability.

- Reviews & reputation - Check independent customer reviews and industry certification to verify their expertise and professional standards.

Since 2003, St Marys Plumbing has established itself as a provider of extensive plumbing solutions, fulfilling every requirement for reliable, superior pipe relining services. Our expert team is celebrated for minimising disturbance and placing customer satisfaction at the forefront, thus earning commendations for subsequent pipe restoration tasks.

Get your bespoke drainage inspections and sage pipe relining Sydney advice favouring relining over major replacement by calling us today on 1300 349 338. With our long-term solutions, we can prevent further leaks, blockages and water pressure issues.