Introduction to Slip Lining and Pipe Relining

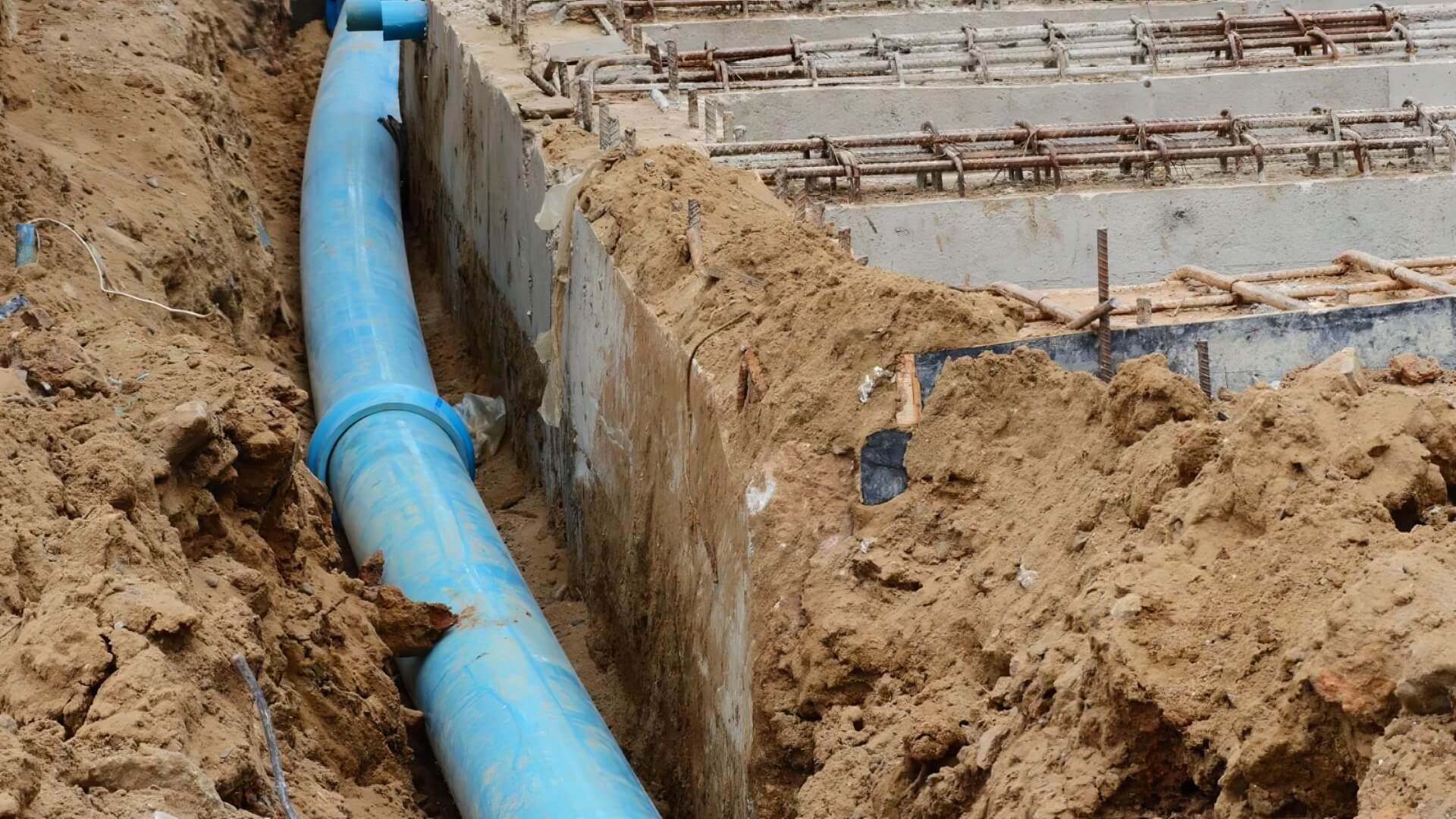

Slip lining and pipe relining, both trenchless sewer repair methods, enable the rehabilitation of damaged sewer pipes without the need for invasive digging. These ingenious techniques provide the installation of a new pipe within old infrastructure, thereby offering savings on time, expense, and the disruption associated with traditional excavation methods.

Pipe relining utilises a distinct method; Pipe relining involves inserting a resin-coated liner into the existing pipe, then curing it in place with hot water or steam to create a solid and robust new pipe layer. When the pipe is cured place using the in situ method, it establishes a brand new pipe that is both jointless and robust. The precision of pipe relining ensures a snugly cured liner even around complex pipe bends and junctions.

Trenchless techniques such as slip lining and pipe relining bolster the structural integrity of pipes, considering the interface between new and existing materials.

Slip lining and pipe relining, both trenchless sewer repair methods, enable the rehabilitation of damaged sewer pipes without the need for invasive digging. These advanced techniques carefully introduce new pipelines into existing infrastructures, saving time, money, and disruption compared to traditional \"open-cut\" replacement.

In slip lining, a new HDPE or PVC pipe, slightly smaller than the host pipe, is fed through the old pipe and left as a standalone \"pipe within a pipe\".

What is Pipe Relining?

Sewer relining employs heated methods, akin to water heater operations, to cure liners with minimal underground disruption. This method places a flexible liner inside the pipe and expands it with hot steam for a precise fit.

Once the liner is cured place using hot steam, the resin acts to form new pipe, culminating in an unbroken and seamless system within the current pipe framework.

In contrast to typical sewer line repairs, using trenchless methods like pipe relining where there’s no need to dig is less intrusive, swifter to establish, and provides superior cost savings for upkeeping your plumbing system. Due to its durability, pipe relining presents an appealing alternative, with the potential to extend sewer line lifespan by up to 50 years.

What is Slip Lining?

It involves sliding in a modern, lesser-diameter HDPE or PVC pipe to set the pipe lining snugly within old one. This newly inserted carrier pipe acts as a robust new structure within the old one, firmly in place.

Given that slip lining minimally reduces the inner diameter, it’s especially suitable for systems requiring new pipe lining like large diameter pipe networks that can tolerate some loss of flow capacity. This approach was very successful in restoring pipelines that were severely corroded, challenging for other repair strategies.

After the new pipe is inserted, the annular space between it and the host pipe is filled with grout or epoxy resin to stabilise it and prevent further damage.

If you’re considering what pipe repair technique to opt for, call us for insights on slip lining as a cost-effective, low-disturbance alternative to pipe bursting, extending the service life of damaged sewer pipes by 50 years or more without the need for digging or replacement.

Key Differences Between Slip Lining and Pipe Relining

Slip lining and pipe relining are both used to repair impaired pipes but have key distinctions:

- Pipe relining forms a new inner layer within the existing infrastructure, melding seamlessly with the existing pipe walls, while slip lining inserts a new, separate pipe inside the former structure.

- Pipe relining maintains almost the full diameter, as the new pipe can be crafted to closely match the original, fitting snugly within existing pipe structures.

- Your pipe relining process can repair cracks, leaks, and minor damage, while slip lining is better for severely deteriorated pipes.

Weighing the pros and cons, pipe relining excels in rejuvenating compromised pipes, maintaining the original size and fluid dynamics. Slip lining is more suited for large diameter pipes with severe damage where reduction in diameter and flow is acceptable.

Materials Used in Slip Lining and Pipe Relining

The following materials are commonly used in both slip lining and pipe relining, including for cast iron sewer pipes:

- High-density polyethylene (HDPE), favoured for slip lining, offers flexibility, durability, and chemical resistance. Trusted brands like Vinidex and Philmac are chosen for their high-quality PE100 pipe products.

- Curedinplace pipe choices, such as CIPP liner, are fashioned for relining to forge a new inner layer within weakened pipes. It is another option for slip lining applications.

- Felt CIPP liners - These liners typify the CIPP method, made of polyester or fibreglass felt coated with thermoset epoxy resin. Upon inflation and curing, the CIPP technique creates a tight, jointless pipe within the existing structure.

- Epoxy resin - Specially formulated two-part resins are used alongside the CIPP liners. They cure at low temperatures for potable water applications.

- Grout or cement mortar - Used to seal the annular space between old and new pipe in slip lining to prevent destabilisation.

Their flexibility and durability make them well-suited for rehabilitating pipes non-invasively to extend service life.

Installation Process for Slip Lining

Slip lining’s installation process consists of these key steps:

- Complete a thorough camera inspection of the damaged pipe to determine access points, location of faults, the extent damage, pipe diameter, and length pipe and bends.

- determine the pipe dimensions and design a polyethylene (PE) slip liner to suit the length of pipe being addressed, and with a marginally smaller outer diameter to slot inside the old pipe.

- Transport the PE liner pipe sections to the access point and fuse them together using electrofusion welding to attain the desired length.

- Attach a winch cable to the front of the PE liner using a tapered pull head and skids for protection.

- Lubricate the outer surface of the liner pipe with bentonite clay to reduce friction.

- Use a power winch to carefully pull the liner into position inside the old pipe, distributing tension evenly across all points.

- For lateral connections, there’s no need for traditional methods since remote-controlled robotic cutters are employed to effectively create openings in the liner and restore service.

- Grout is prepared based on the annular space and pumped with pressure into the gap between the old pipe wall and new liner.

- Once the grout sets and cures, the replacement pipe establishes firm structural integrity in place for long-term service.

The slip lining process takes 4-7 days depending on pipe length and site conditions. Experienced personnel can install over 100 metres per day.

Installation Process for Pipe Relining

Installing a new lining using the cured-in-place pipe (CIPP) process involves these critical steps:

- Inspect the damaged pipe thoroughly with a CCTV camera to identify problem areas and take measurements.

- Cut felted CIPP tube liner to the length of the pipe section being repaired, with an additional 10-20cm on each end.

- Coat the liner with a thermosetting, coated special resin, allowing it to cure partially before installation.

- During installation, the resin-coated liner is introduced into host pipe through an access point and then expanded with air to conform to the interior pipe contours.

- Circulate hot water or steam through the liner to evenly warm it, prompting the resin to cure in place using hot temperatures for a firm and durable fix.

- Maintain pressure for several hours while the liner cures in place, bonded tightly to the old pipe.

- Once cured, perform a CCTV inspection and reconnect service laterals to the plumbing pipe system if required.

The CIPP lining process is minimally invasive and can usually be completed via a single access point within 1-2 days. The seamless epoxy liner is designed to last 50 years or more if properly installed.

Comparing the Advantages and Disadvantages

When considering slip lining vs pipe relining, both trenchless methods have their own pros and cons:

- Cost: Meanwhile, slip lining is more economically viable for large diameter pipes within old sewer systems.

- Pipe Sizes:

- Flow Capacity:

- Pipe Damage:

- Access: Pipe relining usually requires access points for both entry and exit to get the job done, while slip lining needs just an entry point.

- Process Time: Pipe relining takes 1-2 days with minimal disruption. Slip lining takes 4-7 days including grouting time.

In summary, pipe relining is particularly suitable for small-to-medium diameter pipes with minor damage. Slip lining accommodates larger, more deteriorated pipes better but involves more steps.

When to Use Slip Lining vs Pipe Relining

Determining whether to use slip lining or pipe relining depends on several factors:

- For pipes 25mm to 300mm in diameter, pipe relining is often the preferred method of rehabilitation. It maintains close to full diameter and flow capacity.

- For pipes larger than 300mm, slip lining is typically more suitable and economical, given its flexibility for various diameters. The diameter reduction is less impactful for wider pipes.

- Slip lining offers a robust solution for pipes with severe deterioration, including misalignments and collapsed sections.

- Slip lining requires fewer access points, even in challenging intermediary access scenarios.

- If quick installation and return to service is critical, pipe relining can be done in 1-2 days from start to finish.

In summary, evaluating the pros and cons, pipe relining suits small to medium, moderately damaged pipes that require restored flow capacity. Slip lining works better for large, severely impaired pipes when diameter reduction is viable.

Cost Comparison Between Methods

When considering cost, both slip lining and pipe relining offer significant long-term savings compared to full pipe replacement requiring extensive excavation and restoration work.

The upfront material and installation costs of slip lining tend to be lower than pipe relining for large diameter pipes above 300mm. For smaller pipes, pipe relining is generally the more affordable rehabilitation option.

Factoring in the ongoing service life, pipe relining provides exceptional value for money. It can extend the lifespan of damaged pipes by 50 years or more for 60-70% less than replacement, making it hugely cost effective.

Slip lining, while having a higher initial outlay than traditional pipe replacement, also grants decades of extended service life to severely deteriorated pipes. This high return on investment means dramatically lower costs in the long run.

The cost-effectiveness makes them extremely financially attractive options for rehabilitating pipes without digging or disruption.

Environmental Impact of Trenchless Methods

Trenchless repair methods such as slip lining and pipe relining are significantly more environmentally friendly than traditional open-cut replacements. Since they require minimal excavation, they reduce disruption to streets, landscaping, and infrastructure.

These trenchless methods reduce noise, airborne particles, tremors, and carbon output without the need for heavy excavation in your yard. They also protect surrounding soil stability, vegetation, and tree root systems from damage.

Shorter project durations also lessen impacts like traffic delays or access restrictions.

These trenchless techniques extend your plumbing’s service life and reduce waste by avoiding full pipe replacements. Their green credentials make them the responsible ecological choice for pipe rehabilitation.