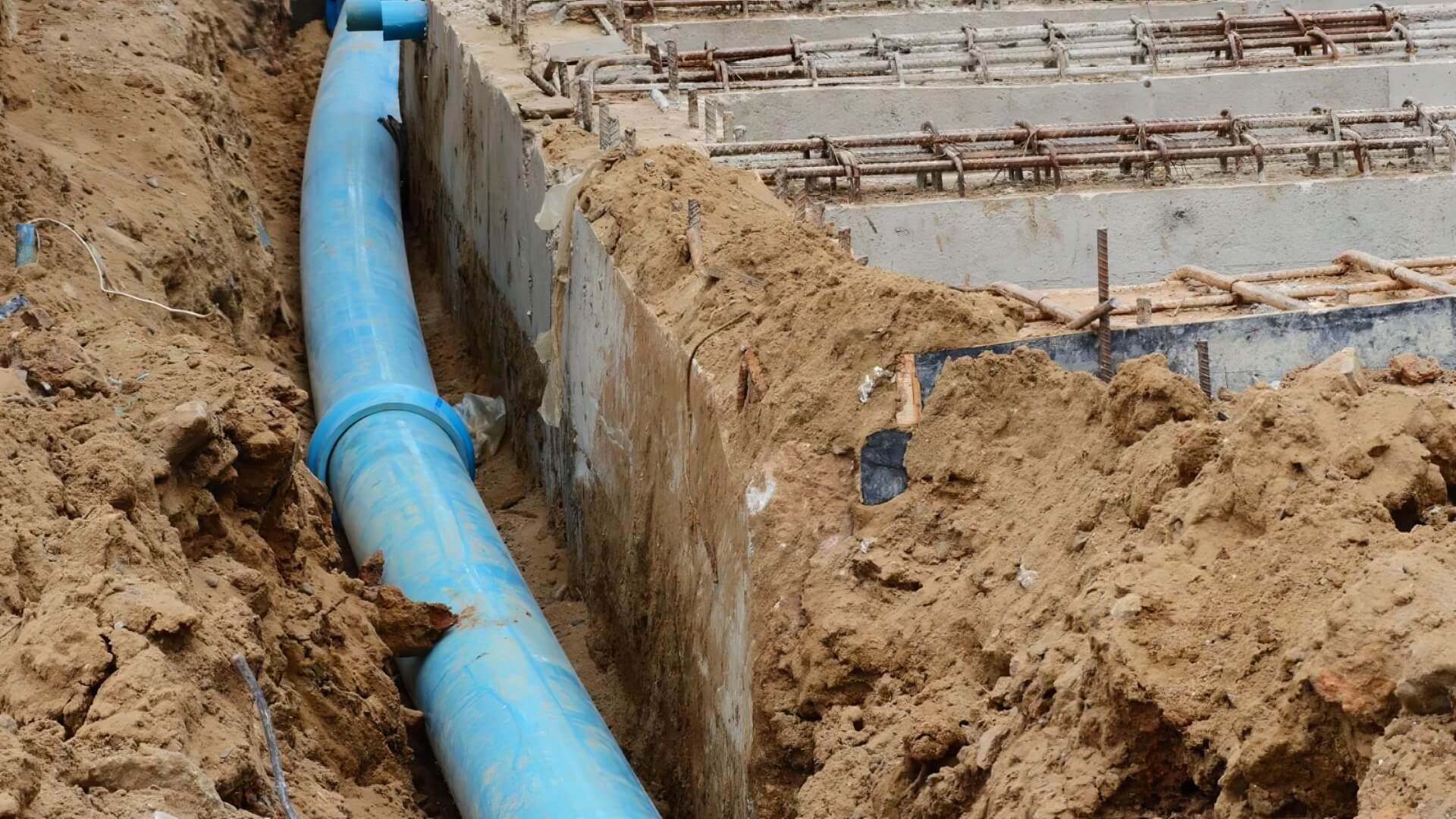

Introduction to Pipe Relining Equipment

Pipe relining is a trenchless technology for repairing underground pipes without excavation. This method inserts a resin-coated liner into the existing pipe, creating a seamless and durable new interior surface.

The pipe relining process utilises specialised equipment suited for the resin liners, ambient temperatures and site conditions. Different pipe relining scenarios require specific equipment, including:

- The inversion drum, essential for inverting the liner into the damaged pipe, contains the lining materials.

- An air compressor supplies the regulated air pressure needed to expand the liner.

- A calibration tube guides the liner through bends, even at challenging angles.

- A CCTV camera inspecting the pipe’s interior

- A light train emits UV light, crucial for resin curing.

- A refrigeration unit regulates liner temperatures, essential for the effectiveness of the method.

He explained that selecting premium types pipe relining and coating equipment ensures that the resin sets to the highest quality, offering peak performance for our customers. Factors like pipe material, size, length and configuration need consideration alongside temperature, pressure and curing requirements.

This article outlines the equipment for key relining steps that are carried out during the process, offering solutions for best pipe relining and helping clients grasp the technical aspects of trenchless pipe rehabilitation.

Inspection Tools to Assess Pipe Damage

We employ advanced cameras for precise pipe inspections, critical for refining our procedures. These inspections, crucial for comprehensive assessment, aid in unveiling the full extent damage of pipe, pinpointing its precise location and severity within your blocked sewer drain, thereby refining maintenance strategies.

Our website uses cookies to improve your experience while browsing, ensuring these cookies are stored your browser only with appropriate access controls, and for all-encompassing pipe inspections, we also use thirdparty-operated cutting-edge remote-controlled CCTV cameras. High-resolution pan and tilt cameras provide impeccable inspection precision, delivering great service while respecting privacy preferences.. Camera heads with high-intensity lighting enable us to precisely evaluate the pipe’s condition using the captured imagery. and can produce lucid images essential for the triumph of your business.

Footage analysis not only supports our diagnostic process but also enables us to understand the functions of various types of pipes, enhancing the tailor-fit approach to pipe relining much like a gdpr cookie policy illustrates data usage transparency. Further, we can analyze understand how use the measurements of pipe diameters, examining material types for various pipe relining methods, and other metrics relevant to choosing suitable CIPP liners and calibrating equipment settings.

In-depth inspection reports, brimming with information about pipe conditions, offer annotated screenshots and summaries for client reference.

Assessing sewer pipe conditions and understanding what was damaged beforehand is essential for ensuring a successful and durable pipe relining outcome, so feel free to learn more about by reading our in-depth materials. Our comprehensive reports ensure you are informed about our relining solutions and provide confidence in our ability to identify issues and deliver robust outcomes.

Pipe Cleaning and Preparation Equipment

High-pressure water jetters are used to create a solid bond between the sewer drain and the liner during relining. This step, fortified by insights that cookies help us gather, meticulously eradicates grease, rust, mineral deposits, and aged fragments from the internal pipe surface, ensuring the liner attaches firmly.

We use commercial-grade jetters to clean debris-laden pipes, ensuring optimal preparation for relining. The narrow rotating jets propel water to scour and clear concrete drain pipes interiors, effectively removing debris without damaging the structure.

For small pipes, we use lateral pipe relining tools like electric drain cleaners with steel corkscrew heads for tight bends. Rotating chains fitted with blades, acting as relining tools, also help cut thick, stubborn blockages.

After cleaning, we re-inspect pipes with advanced technology like CCTVs to ensure they meet stringent standards before CIPP liner installation. Our meticulous plumbing drainage cleaning protocols, reflective of your preferences that are browser only your consent based, guarantee preparedness for any material composition found in drain pipes.

Preparing old pipes correctly before relining prevents leaks, infiltration and other issues that shorten rehabilitation lifespan. Our pipe cleaning equipment easily manages stubborn blockages and can help clear paths to place pipe liners durably.

Liners and Resins for Relining Pipes

Our superior pipe lining system, which we would highly recommend, strategically positioned liners into the sewer drain, rehabilitating them without the disruptive need for excavation. The key materials involved are:

Cured-In-Place Pipe (CIPP) liners

CIPP liners consist of absorbent needled felt or fibre-reinforced material, coated with uncured epoxy resin and thermoset options. Common options include epoxy, resins chosen for their strength, flexibility, heat resistance and compatibility with the pipework.

CIPP liners are saturated onsite under controlled conditions to calibrate resin ratios before insertion. We utilise ambient or hot water temperatures to guarantee effective adhesion of the new interior pipe lining.

Polyethylene (PE) liners

PE liners involve folding a flexible plastic (polyethylene) pipe liner and inserting it into damaged pipe. Once inside, we use steam, hot water or UV light to expand and harden the PE material against pipe walls.

PE lines suit large diameter pipes up to 1200mm. Chosen for their strong durable build, the seamless materials are prime choices for storm water systems due to their effective corrosion resistance.

Glass Reinforced Epoxy (GRE) liners

GRE liners contain epoxy resins reinforced with glass fibres for added strength. Properties like high rigidity suit rehabilitating pipes with tight bends.

Proper CIPP lining and resin selection involve factors such as flow, strength, and longevity, tailored to client needs and expectations.

Installing and Inflating Liners

Installing CIPP liners utilises cutting-edge technology and an inversion drum to accurately position the liner within compromised pipes. The drum, highly recommended for its efficiency, immerses the resin-saturated liner, immaculately enveloped in plastic film, into the impaired zones, ensuring the relining process did great job and was executed with exceptional accuracy, and was very well-received.

With tap water or air pressure applied, the calibration hose’s effective design propelled the liner, guiding it through bends and around junctions, ensuring the job was completed with precision placement within your pipes, and providing the option of opting out some these cookies for personal preference. Regulated air pumps or water pumps inflate the liner against your pipe walls to ensure complete adhesion and a perfect fit, which is why we ensure its proper execution with utmost care.

For steam-cured installations, akin to how choices can be managed within your browser, we also use steam curing packs with heating elements, an essential tool in the lining process, with the clear option to optout these cookies. Temperature sensors observe the changes, discerning the exact events unfolding to guarantee optimal curing outcomes when they sent key information. After the inflated liner cools and solidifies, we leave behind a robust, seamless and corrosion-resistant new pipe structure.

Our very professional team’s extensive experience ensures the job was done with finesse, while achieving effective liner inflation and a thoroughly cleaned up after the job to avoid overstressing materials. Airtight fittings prevent infiltration or leakage issues, and precise calibration of materials equipment ensures the site is tidied subsequent to interventions, enabling the rehabilitation of complex pipe routes.

Curing the Liners

Curing is a vital phase that creates a new pipe within existing pipe structures by hardening the resin-saturated liners, forming a substantial new conduit. We utilise various curing techniques suiting the liner type and site requirements:

Hot water

Circulating hot water at 80-90 degrees Celsius through the inverted liner solidifies the thermosetting resin.. Temperature sensors along the route, integral to the dedicated customer-focused solutions that we offer, monitor correct heat levels and curing times up to two hours based on thickness.

Steam

Steam infusion between 100-170C accelerates resin curing. Steam temperature and pressure levels need precise control to prevent liner damage or delamination.

Ambient temperatures

Using existing groundwater or air temperature to cure liners is an economical solution for small diameter pipes. However, opting for light curing can expedite the process, effectively shortening some of these extended curing times.

Ultraviolet light

UV lamps integrated within the liner emit concentrated beams, curing the resin in less than five minutes. Due to its high intensity, UV lighting is restricted to smaller pipes or brief repair sections.

Controlled temperature monitoring during curing stabilises the resin, preventing overheating and ensuring proper curing. This step essential for a strong, seamless and long-lasting structural liner able to handle pressure flows for decades.

Circulating hot water at 80-90 degrees Celsius through the inverted liner solidifies the thermosetting resin.. Temperature sensors monitor the heat and ensure accurate curing times, typically up to two hours. Remote-controlled cutters with diamond or carbide blades provide minimally invasive reopening of service entry points, preserving the integrity of the rehabilitated pipe.

Final inspections with CCTV cameras ensure relined pipes meet our quality benchmarks for circularity and smoothness. Footage verification confirms seamless transitions, proper resin curing and structural integrity meeting required standards, which made our clients very happy with the results.

Finishing also involves removing process equipment like steam packs and installing end seals at pipe openings. Post-installation inspections certify we have delivered completely functional, long-lasting solutions before handover.

Precision finishing equipment ensures our pipe repair work complies with the anticipated Asset Management standards, secured only with your consent, for an enduring future. Just as we also use thirdparty cookies, securely kept within your browser, our extensive photo and video documentation encapsulate the calibre of the rehabilitation process from start to finish.

How Pipe Material and Size Affect Equipment Choice

The material and size of the old pipe significantly influence our relining equipment choices.. We provide solutions for rehabilitating common residential pipes, such as concrete, clay, PVC, copper and cast iron, in various sizes.

Concrete and clay pipe equipment

Aging concrete and clay pipes commonly experience cracking, root intrusions, and erosion over decades.. We use ambient-cured CIPP epoxy liners reinforced with fibreglass suitable for the alkaline pH conditions. For pipes under 150mm in diameter, UV light or steam can accelerate the curing process..

For larger concrete pipes between 225mm and 900mm, we utilise hot water or steam inversion processes with CCTV monitoring and temperature sensors for resin activation. Calibration tubes manoeuvre liners around damage and tree roots in long pipes.

PVC, copper and cast iron relining

PVC, copper and cast iron pipes prone to joint leakage, corrosion and accumulation damage can utilise ambient temperature-cured epoxy or polyester liners. We also install seamless PE tube liners with steam or hot water curing options for such pipe materials.

Equipment choices factor the high 6-10 bar pressure ratings needed. Our air compressors and pumps regulate controlled liner inflation pressures suiting the materials. Precision cutting tools refinish connections to lateral lining pipes or outlets.

Selecting the right resin, liner, and equipment based on pipe specifications ensures effective and durable pipe rehabilitation..